The International Maritime Organization’s (IMO) initial strategy on greenhouse gases (GHGs) is driving system integrators and shipping companies towards new and more energy-efficient solutions. The goal is to meet IMO's GHG emission reduction targets.

“(…) we are behind schedule when it comes to the global transition towards zero-emission shipping – far behind. But now we are speeding up and the momentum is growing.”

– Mr. Sveinung Oftedal, Chair, IMO GHG Working Group

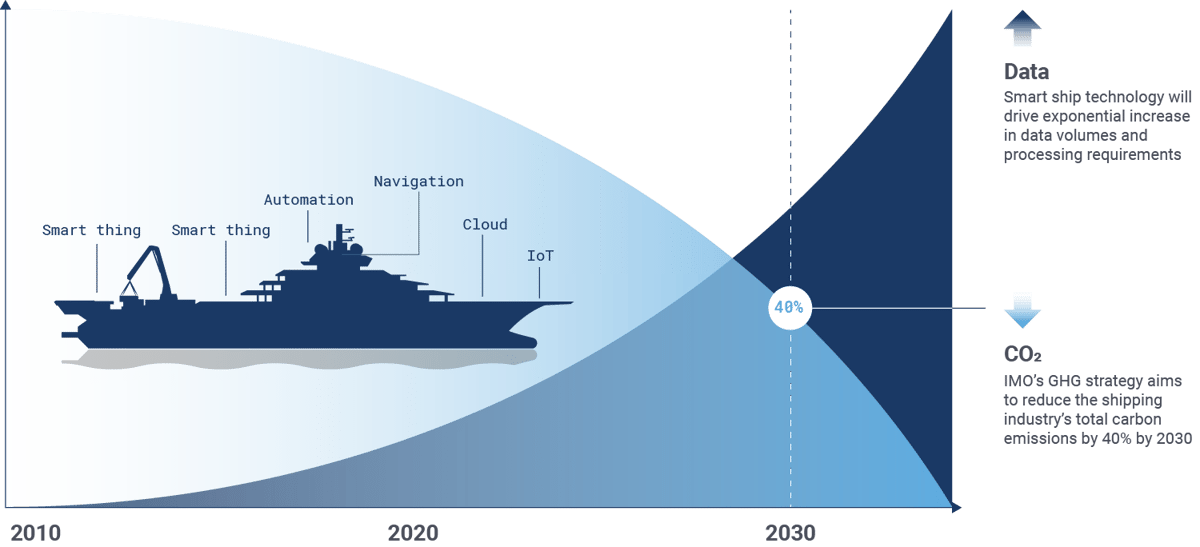

IMO’s initial GHG strategy aims to reduce carbon emissions by 40% by 2030 (IMO 2030) from 2008’s levels and at least 50% of the shipping industry’s total greenhouse gas emissions by 2050 (IMO 2050).

To that end, shipping companies and ship owners have begun upgrading their fleets, investing in new hybrid and electric vessels, as well as retrofitting current ships with innovative smart ship technology. But what exactly do we mean by smart?

We take a closer look in this article, but here's the brief: You can consider things or systems smart when they

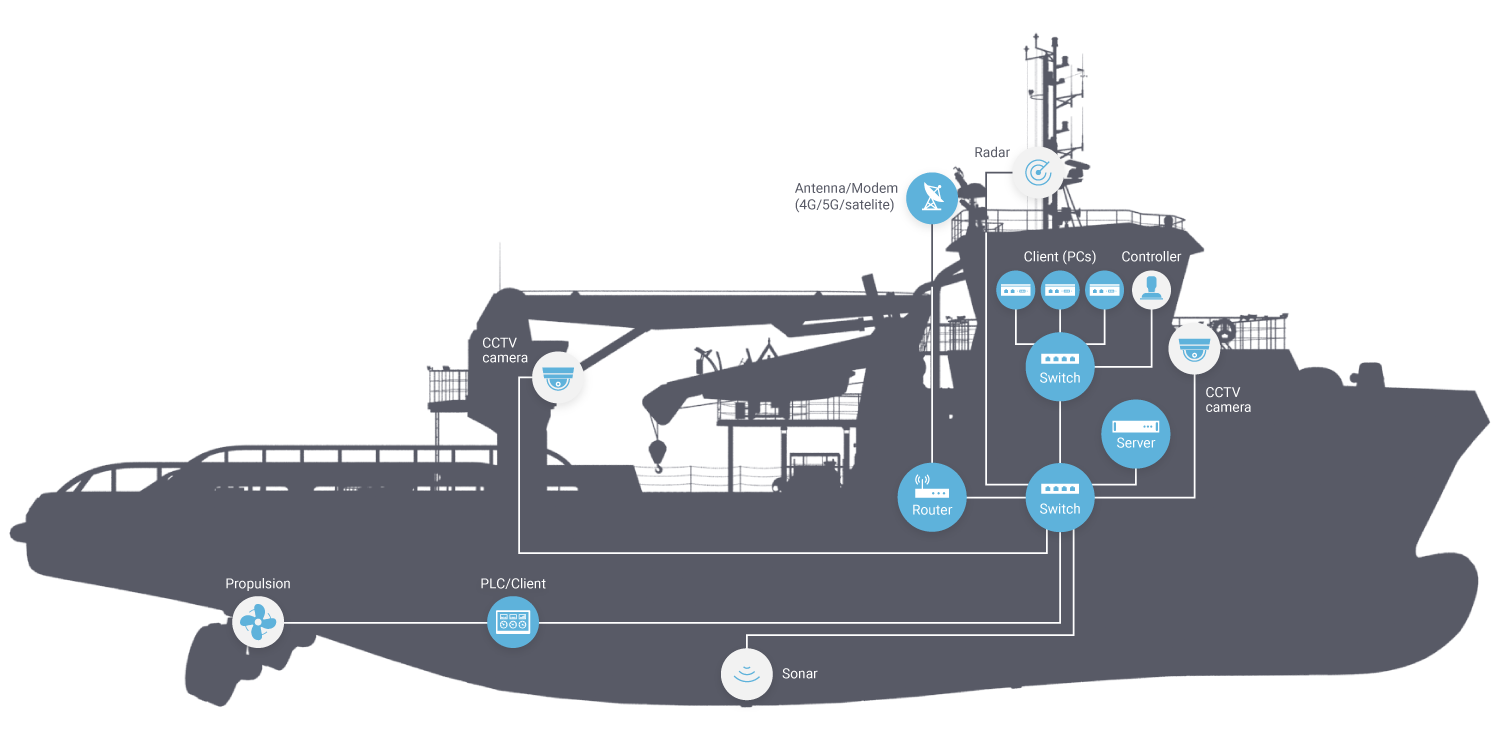

These capabilities don’t just appear out of thin air, of course. For the smart ship development to materialize, fleets need digital infrastructure. Onboard computer networks play a key role.

Let’s take a closer look at the technology that enables the smart shipping industry.

Computer networks on board ships |

|

|

What |

Role |

|

Modem |

Connects the ship to the Internet. |

|

Router |

The router 1) enables units/users to share the single Internet connection and 2) routes traffic between the local network and external networks. |

|

Switch |

Directs traffic within the local network. |

|

Server |

Servers host shared resources (like the network operating system) and process data from sensors and devices. |

|

Clients (users) |

Units that allow you to access and use the network are known as clients. Computers, cell phones and PLCs are a few examples. |

|

Cables/wires |

Data passes through the network via cables, also referred to as wires. Many networks combine hardwired- and wireless connections. |

|

Peripherals |

Necessary for the input, output, and storage of data. |

If you think this looks like what you’ll find in any other industrial computer network, you’re correct. Land-based computer networks and maritime computer networks are, in principle, the same.

But the sea is a uniquely challenging environment for IT technology.

Ships routinely grapple with harsh conditions and environments and are subject to rigid requirements and regulations for safety and security. Factors to account for include:

…and the list goes on. Thus, it's paramount your network hardware is ruggedized and tested for marine applications. But that’s not all it takes to secure a network.

Smart ships, too, must endure harsh conditions.

– David Emm, principal security researcher at Kaspersky, to CNBC.“The reality is that an aeroplane or vessel, like any digital system, can be hacked.”

If this topic hits home with you, perhaps you’d like to know a little more. Here’s an article where we explore why the above systems are vulnerable, and what steps you might take to boost your defenses.

Knowing your weak spots is good. Strengthening them is even better. For that, choosing the right hardware goes a long way.

Below, you'll find a selection of ideal hardware for the cyber-security-conscious shipowner. If you're curious what makes these units particularly adept at protecting your data, we provide more details in this article. In short: They combine top performance with strong, inbuilt cyber-defenses—and they handle tough, physical environments. Hence their certifications.

|

|

|

|

|

Industrial computer/server |

Smart monitor |

Surveillance camera |

|

|

|

|

|

All-in-One Industrial Secure Router |

Industrial managed switches |

|

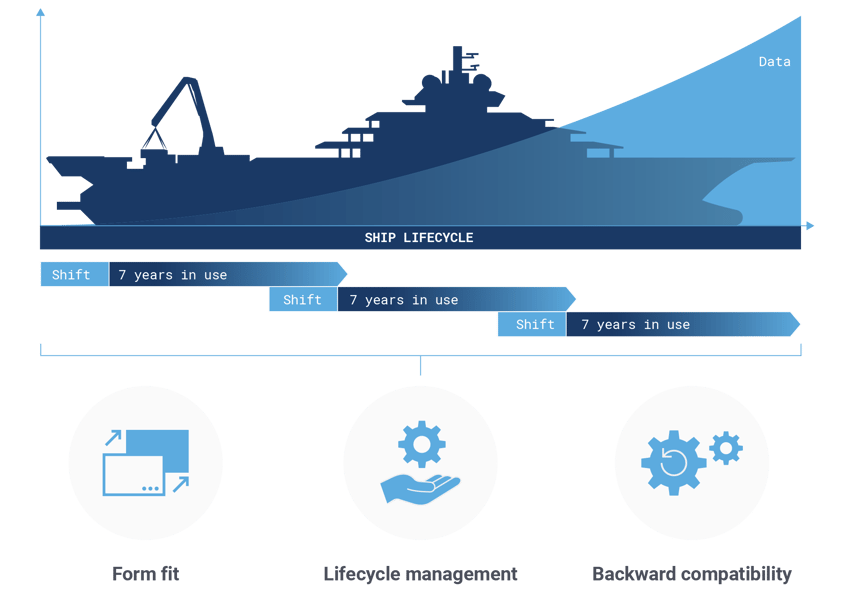

On average, electronics change every seven years. This poses a challenge to shipowners and system integrators: How do you keep your vessel up-to-date throughout its 25-year lifecycle?

A future-proof strategy involves three key concepts: 1) form-fit, 2) lifecycle management, and 3) backward compatibility. Together, they ensure that all systems and hardware are capable and prepared to support data volume and processing requirements seven years into the future, and – when changes must be made – enable a smooth transition.

Upgrading core systems to implement smart ship technology will increase data volumes and processing requirements, as improved data (i.e. better weather data, navigational data, sonar, and radar) provides greater control of ship’s systems – which in term leads to more energy-efficient decision making and a reduction in carbon and GHG emissions.

This exponential increase in data volumes and processing requirements means that system integrators and original equipment manufacturers need smarter and more powerful hardware, to facilitatethe smart ship technology that will enable the shipping industry to realize IMO 2030 targets.

3 key requirements for a seamless technology shift

In our age of rapid technological advancement, the marine and offshore industries are constantly searching for new ways to take advantage of the latest benefits of the technology tidal wave.

Read article

Outfitting a handful of Norway’s most famous seafaring vessels with tailor-made CCTV systems is just the most recent chapter in a successful partnership spanning two decades.

Read Article

A reliable innovation partner will work closely with system integrators to create a comprehensive solution that satisfies your client’s current requirements and facilitates cost efficient options for future development.

Read Article