IN-HOSE TECHNOLOGIES

Color calibration for ECDIS

All units verified

We calibrate and verify every single one. No exceptions.

Color tables stored in monitor's flash memory

For effortless integration with the ECDIS computer.

Proprietary method

We've made color calibration an integrated part of our manufacturing.

35+ years of maritime experience

Everything we do is rooted in end-user insights.

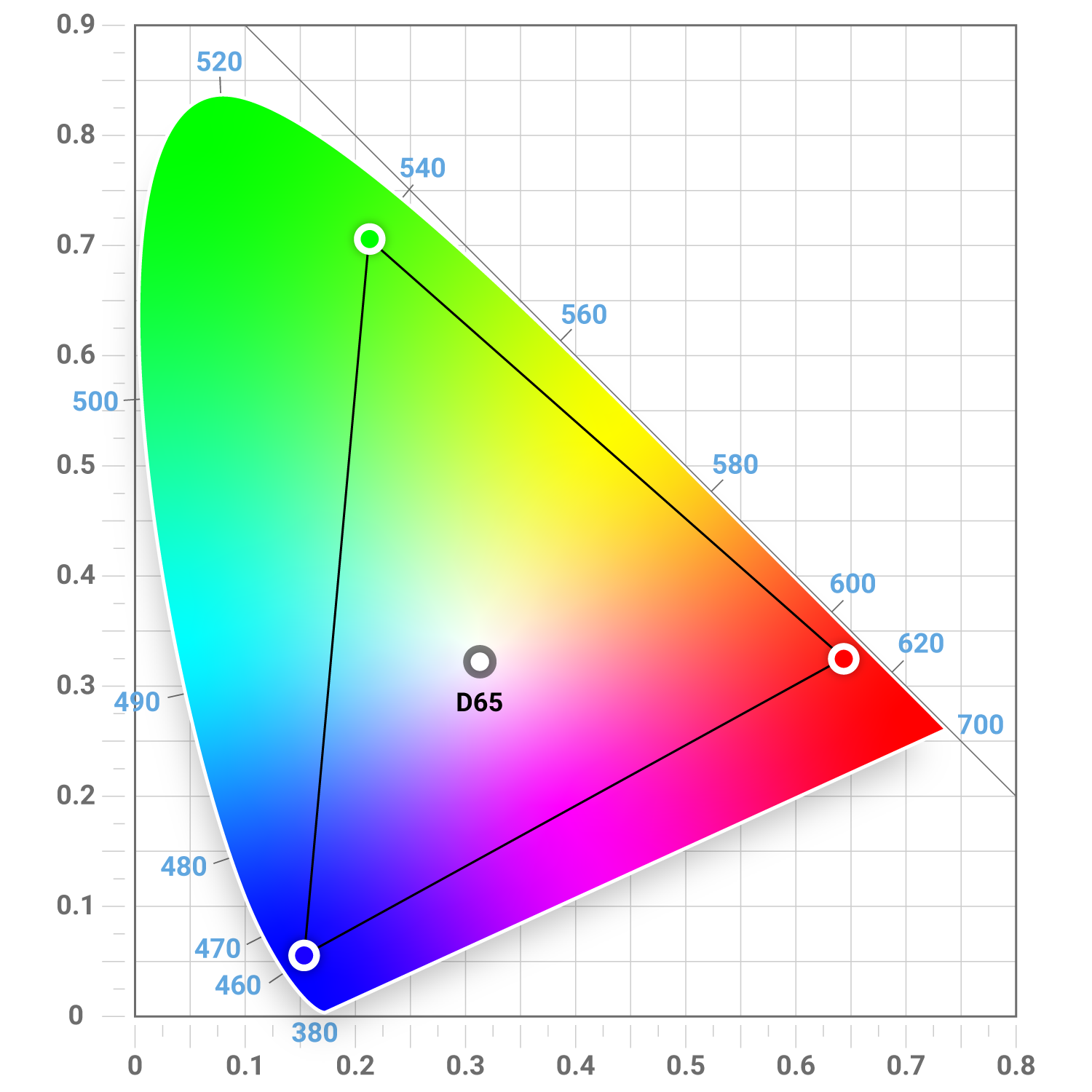

"Through color calibration, you ensure all colors defined in an ECDIS are correctly displayed on the surface of the LCD."

- Mr. Jakub Kwiatkowski, Head of R&D

The importance of color precision

The colors on nautical charts are of vital importance to navigators. Colors make elements distinguishable and carry information about depths, direction lights, submerged pipelines, and many other safety-critical factors.

With electronic chart tables increasingly replacing paper charts, it's crucial they present colors accurately. If not, navigators run the risk of misreading the chart due to deviations across lighting conditions.

Why color calibrate?

-

Color precision is vital to navigators’ understanding of the surroundings.

-

It is a prerequiste for ECDIS monitors (IHO).

-

Color-calibrated displays offer optimal readability at all times, during the day, at dusk, and at night.

-

Mariners commonly swap between paper charts and ECDIS monitors.

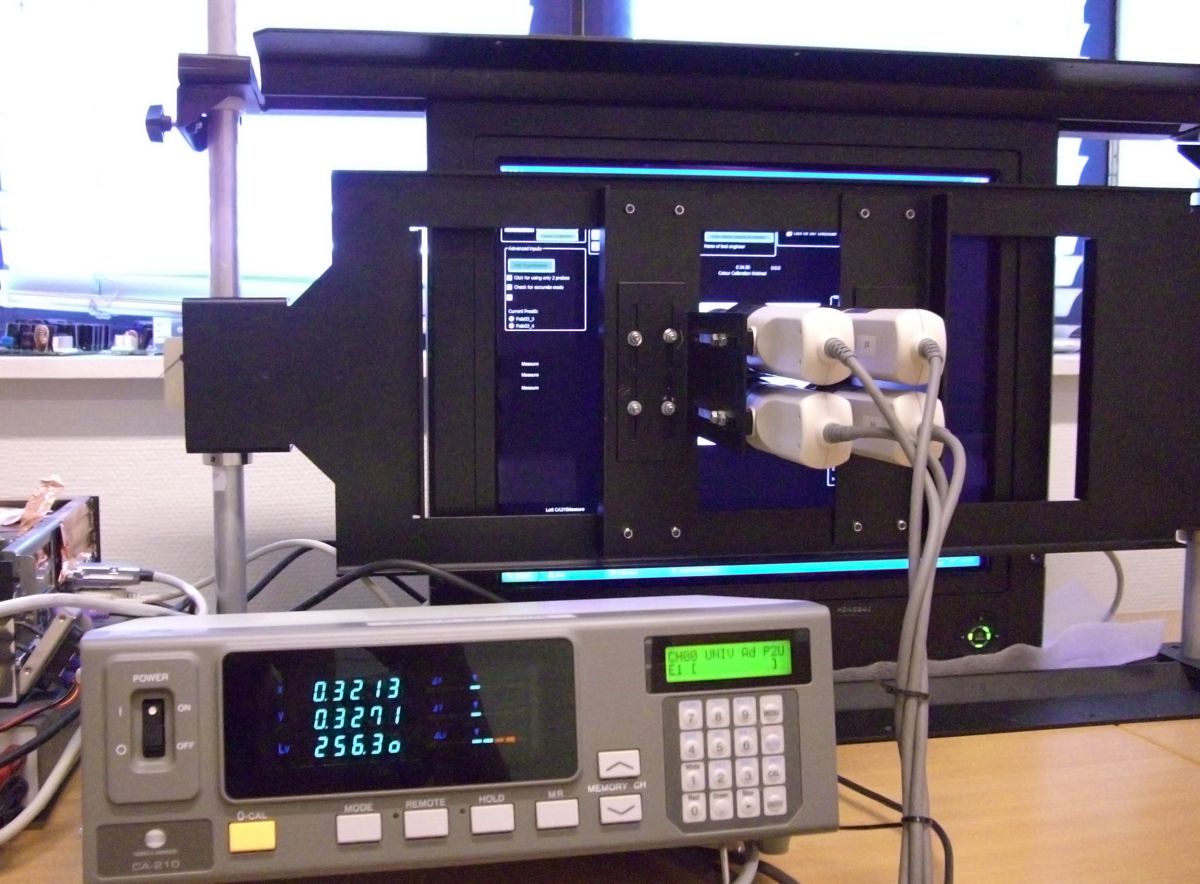

An integrated part of our production process

Hatteland Technology has developed a tried and tested process for color calibration. It meets all the requirements for type approval, and is one of the most convenient installation-/configuration processes on the market.

Our production line is equipped with the full range of facilities to both calibrate and verify our monitors in preparation for ECDIS integration.

Your technology partner

Having manufactured maritime monitors for several decades, color calibration for ECDIS is second nature to Hatteland Technology.

At our HQ in Aksdal, a team of seasoned professionals ensure the first-rate performance you expect from a Hatteland Technology device.

We verify every single unit

One might assume two identically manufactured monitors will present colors equivalently, but that is not the case. No two displays behave exactly the same out of the box — even if they’re of the same batch.

To address these deviations, Hatteland Technology calibrates and verifies every single unit. We ship all our ECDIS monitors with unique color-correction values embedded, so that the ECDIS computer can call on a reliable reference when presenting color-sensitive information.

Explore our other in-house services

Optical bonding

Optical bonding reduces display glare in bright environments. It is considered a must-have by many professional users.

Learn moreType approvals and testing

Using in-house and third-party facilities, we test and certify your hardware for all kinds of environments.

Learn moreWant to learn more?

In this article, we discuss color calibration, the associated IHO standard, and what to look for in a supplier.

OUR PEOPLE

Hatteland Technology offers a complete delivery: Project engineering and -design, hardware, testing, prepping, procurement, and servicing. Want to know more?

Meet the team