IN-HOUSE TECHNOLOGIES

Optical bonding

Reduce glare

Many professional users consider anti-reflection treatment a must.

Stop particle contamination

The resin used in optical bonding keeps particles out...

Prevent condensation

...and fills the cavity where moist air might otherwise enter.

Dampen vibration and shock

The polymer material cushions the impact in the event of mechanical stress.

"Optical bonding is the art of eliminating reflections from displays."

- Mr. Jakub Kwiatkowski, Head of R&D

Don't squint. Navigate.

If you’ve ever spent time on a ship’s bridge, you know how bright an environment it can be. The vast window area helps you get a good outlook, but intense sunlight can compromise the readability of your displays.

Unless you’re equipped to handle it.

Optical bonding and other anti-reflective treatments help keep your visual data as sharp as your senses.

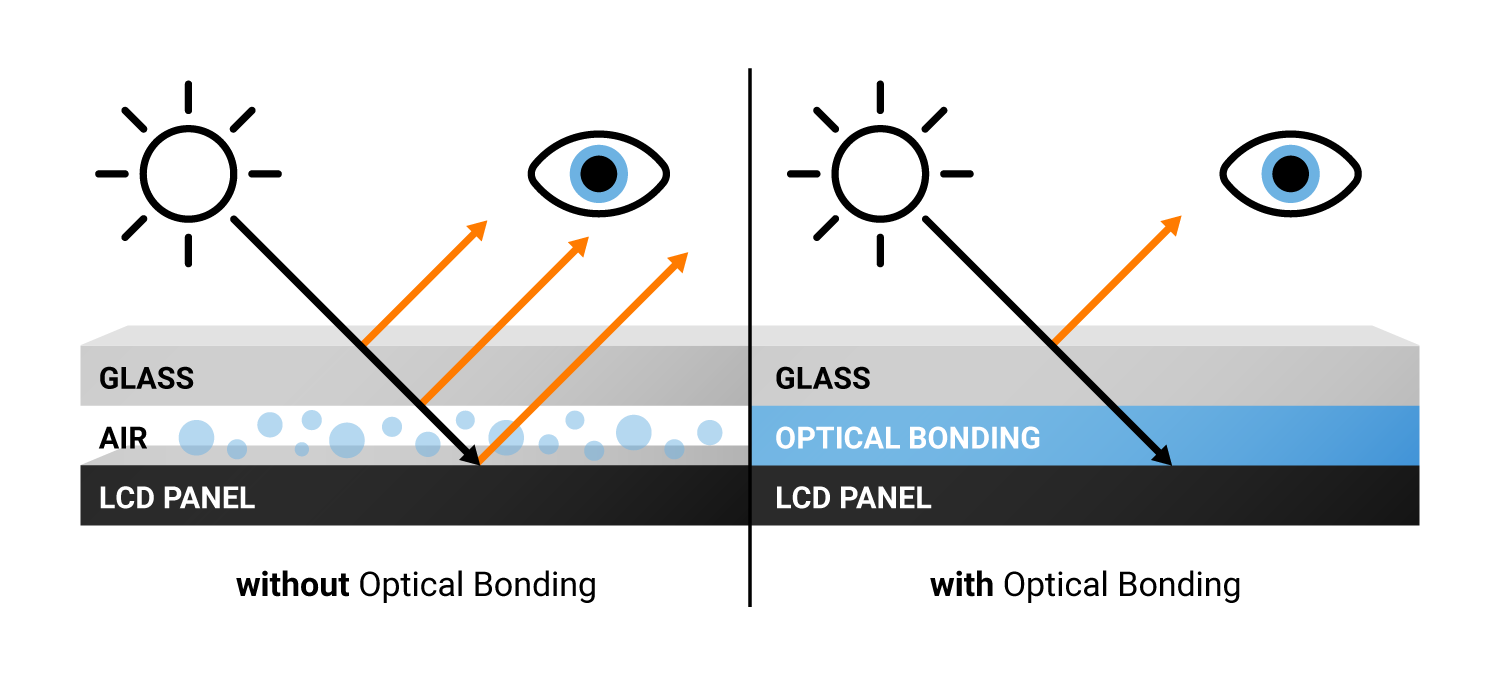

How it works

- We treat the front glass with a high-quality,

anti-reflective coating.

- We use a resin to fill the air gap between the LCD panel and the front glass. This “bonds” the two surfaces, eliminating reflective surfaces.

- Once complete, the treated monitor offers excellent readability in all lighting conditions.

A must for electronic chart tables

With their prominent placement on ships' bridges, maritime monitors and electronic chart tables benefit greatly from optical bonding.

Case in point: Stellar anti-reflective capabilities help make the

Hatteland® Series X MVD 55-inch (pictured) the ultimate unit for route planning and navigation — even in bright sunlight.

We’ve done it for decades

Due to our extensive experience with maritime IT hardware, optical bonding has been a core skill for Hatteland Technology for almost 20 years.

At our HQ in Aksdal, we have a fully-equipped lab staffed by a team of professionals who ensure the pristine optical performance you expect from a Hatteland Technology device.

Available for all our displays

We offer optical bonding for monitors and panel PCs of all sizes, from our smallest devices all the way up to our flagship, the 55-inch electronic chart table.

Explore our other in-house services

Color calibration for ECDIS

We use an industry-leading method for color calibration — a prerequisite for certification of ECDIS displays.

Learn moreType approvals and testing

Using in-house and third-party facilities, we test and certify your hardware for all kinds of environments.

Learn moreWant to learn more?

Read our in-depth article on optical bonding, featuring optoelectronics engineer and head of R&D at Hatteland Technology, Mr. Jakub Kwiatkowski.

OUR PEOPLE

Hatteland Technology offers a complete delivery: Project engineering and -design, hardware, testing, prepping, procurement, and servicing. Want to know more?

Meet the team