|

As described in annex B of the C&S Specifications, ECDIS manufacturers are responsible for computing the correct RGB values from CIE values, for the monitors that they use in their systems. Hatteland Display supports the leading ECDIS manufacturers by providing an in-house calibration system that defines the proper RGB values, allowing the delivery of calibrated ECDIS monitors from the factory.

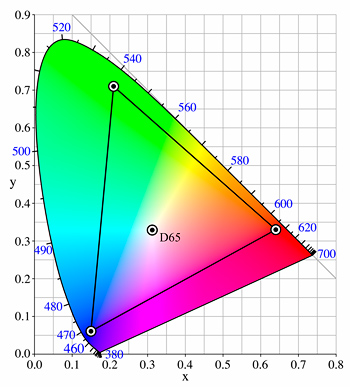

The primary aim of this calibration is to reproduce the correct color distinctions needed to distinguish between different symbols and other crucial information on the display. Calibration defines the monitor performance in terms of the relationship between input signal and the color and luminance output on the screen and is performed for each of the red, green, and blue (R, G, B) channels. The signal that drives the monitor is specified in terms of three DAC (Digital to Analog Converter) values – one each for R, G, and B. These are usually from 0 to 255, and color is specified in CIE co-ordinates of x-y, and luminance (L) in candelas per square meter. The DAC values are programmed within the image generator to generate specific colors required by the system.

ECDIS manufacturers can choose between two different methods of calibration as mentioned above. The first method is a test of a monitor as part of an integrated system, often referred to as ECDIS ‘calibration’. In this test, a unique color correction table is created for each monitor, which is stored in the monitor’s flash memory. The ECDIS software must download the table and use it to correct the output from the ECDIS computer. The second method is an independent test of the monitor. In this method the monitor and the image generator of the ECDIS display are separately tested against a reference (i.e. the monitor is tested against a reference image generator and the image generator is tested against a reference monitor). The second method has tighter tolerance for displayed color than the first method. ECDIS manufacturers can choose between two different methods of calibration as mentioned above. The first method is a test of a monitor as part of an integrated system, often referred to as ECDIS ‘calibration’. In this test, a unique color correction table is created for each monitor, which is stored in the monitor’s flash memory. The ECDIS software must download the table and use it to correct the output from the ECDIS computer. The second method is an independent test of the monitor. In this method the monitor and the image generator of the ECDIS display are separately tested against a reference (i.e. the monitor is tested against a reference image generator and the image generator is tested against a reference monitor). The second method has tighter tolerance for displayed color than the first method.

On the other hand, when performing color verification, the monitor is essentially calibrated independently of the image generator. In this case, the generator is expected to output a signal that is linear and repeatable from unit to unit. If the accuracy of the image generator output is unknown, then it should be calibrated as an integrated unit with the monitor. In the case of color verification, Hatteland Display takes data using a reference image generator and provides the ECDIS integrator with a fixed RGB table to use in their systems. During production of the displays, Hatteland Display verifies the CIE coordinates of 5 colors prior to shipment to the customer.

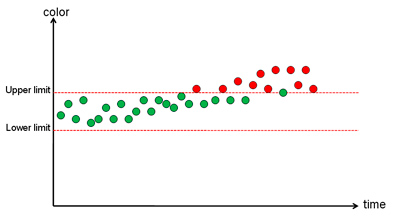

Color calibration is similar to color verification, but instead of using a fixed RGB table, a unique RGB table for each display must be loaded into the ECDIS system. This means that each display can be driven from an individual RGB table, and by that compensate for small shifts coming from differences in batch or color shift from operating hours. However, the logistics problems associated with transferring calibration data with individual displays has traditionally made this approach complicated. Color calibration is similar to color verification, but instead of using a fixed RGB table, a unique RGB table for each display must be loaded into the ECDIS system. This means that each display can be driven from an individual RGB table, and by that compensate for small shifts coming from differences in batch or color shift from operating hours. However, the logistics problems associated with transferring calibration data with individual displays has traditionally made this approach complicated.

Hatteland Display can assist any customer in implementing a color calibration or verification solution, as we have inhouse expertise, a calibration software tool (optimized for ECDIS color measurements) and a production line capable of integrating the process.

Hatteland Display has the ability to perform in-house ECDIS measurements to support both calibration and verification methods.

As a leading supplier of type approved displays, our experience in this area has led to the development of a new, automated ECDIS color calibration system, available for implementation in customers’ own ECDIS software. In this proprietary system, each display stores its own color calibration information, which can be uploaded to the PC via serial communication. This is a plug and play system, which can include safety measures to prevent users from substituting non-type approved monitors in their ECDIS system. It also offers flexibility as displays from different suppliers can be used, and calibration data can be rewritten during maintenance or service to compensate for changes over time.

In addition to the traditional RGB interface, Hatteland’s ECDIS displays also support the Digital Video Interface (DVI) standard. The use of DVI greatly simplifies the calibration process, in addition to improving picture quality, and is highly recommended for new system designs.

|