Color calibration for ECDIS: What it is and why it matters

Roses are red, and violets are…turquoise?

The colors on nautical charts are of vital importance to navigators. They make elements distinguishable, and carry information about depths, direction lights, submerged pipelines, and many other safety-critical factors. No surprise, then, that navigators are required to undergo color-vision examinations during certification.

Conversely, if navigators’ perception of color is important, the colors they are presented must be faultless, too. Indeed, standards IHO S-52 and IEC 62288:2022 specify requirements digital displays must satisfy to gain certification for ECDIS use.

“The ECDIS display carries far more detail than a radar display, and requires correspondingly more attention to the correct selection of colour table and the correct adjustment of the controls."

S-52 (SPECIFICATIONS FOR CHART CONTENT

AND DISPLAY ASPECTS OF ECDIS, Edition 6.1(.1),

International Hydrographic Organization). page 43.

Preparing a display for ECDIS use

Although the digitalization of shipping is only accelerating, paper charts and digital displays will coexist for the foreseeable future. Consequently, they must present information similarly.

The challenge is paper charts reflect light, whereas digital displays emit light. The latter thus need to be prepared for different lighting conditions. In other words, a bit of tuning is called for. Per the International Hydrographic Organization (IHO):

“To ensure clear contrast between colour-coded features the display screen should be calibrated before use, and this calibration should as far as possible be maintained while in service. If this is not done, lines, symbols, and area shades may become indistinct, and information may then be lost or become misleading.”

S-52, page 14

Through color calibration, you ensure all colors defined in an ECDIS are correctly displayed on the surface of the LCD. Done right, you eliminate the risk of misreading the chart due to color deviations across lighting conditions.

|

|

|

| Above: The color schemes of a conventional nautical chart (left), and an ECDIS-approved, electronic chart table (right). |

|

One might think that identical units would have the same color performance, but that is not the case. No two displays behave exactly the same out of the box, even if they’re of the same batch.

To address these deviations, each end every unit is calibrated to account for their differences. That process results in a set of unique color-correction values that the ECDIS uses as a reference when presenting color-sensitive information.

Color calibration ensures units present data uniformly, to the extent they could be interchanged if need be.

The three color modes

Through color calibration you lock in the appropriate colors for different lighting conditions, so that mariners are presented the colors they expect. There are three main color modes: day, dusk/dawn, night. Here are a few characteristics for each of them.

| Day |

| During daytime, when there is lots of ambient light, the screen is set to be bright with vivid, highly contrast-based colors (whites, blues, magentas). |

| Dusk/Dawn |

| At dusk or dawn, as white/black changes to grey, the display starts to invert the chart colors. |

| Night |

| At night, the luminance of area colors is turned down to a minimum. |

To sum up, according to the S-52 standard:

“The ambient lighting on the bridge varies between the extremes of bright sunlight, which washes out information on the display, and night,

when the light emitted by the display has to be low enough

that it does not affect the mariner's night vision.”

How to color calibrate and verify a display

Color calibration for ECDIS takes place in a controlled environment. You take measurements for calibration and verification, as certification for ECDIS requires you to prove the display’s color presentation meets the standard.

In the process, three color correction tables (corresponding to the three modes) are created for each monitor. The correction tables are used to set the output from the ECDIS computer.

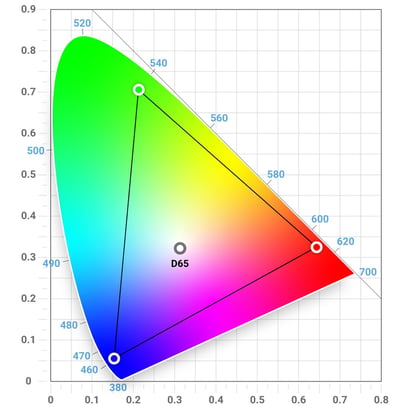

Above: The visible spectrum of the human eye. Color calibration ensures that ECDIS colors,

defined in this space, are represented accurately, and within all their legal tolerances.

Is color calibration relevant for all displays?

Color calibration is a prerequisite if the goal is ECDIS approval. Technically, it can be incorporated for any size of product/device. However, there’s a minimum requirement (height, width, and resolution to name but a few) for units to be eligible for ECDIS use. Units outside that scope would usually not undergo color calibration.

Above: One of the calibration setups at Hatteland Technology's HQ in Aksdal, Norway.

Good to keep in mind

Now that you know what color calibration is, and what it is for, you might find use for a few recommendations going forward.

Be aware of the differences. Many suppliers offer “color calibration for ECDIS” but note that they all use different approaches and techniques. Though they appear to be similar at first glance, certain solutions carry significant benefits compared to others.

One example is whether loading the color tables onto the ECDIS computer is straightforward or cumbersome. Options here range from manual input via printed tables (complicated) to values automatically loading from the monitor’s flash memory (easy).

Consider the complete picture. Considering the highly technical nature of color calibration, and the extensive life span of industrial monitors, make sure your supplier has an ecosystem to match.

Whether you need additional units, or servicing of current ones, it is important to work with a partner who understands the science of optoelectronics, the maritime industry, and your needs related to the full range of onboard applications.

Remember, color calibration is only a part of ECDIS requirements. To comply with a standard, you must consider many other aspects of the design and performance of the monitor or panel computer. Do thorough research into your ECDIS system to make sure the setup as a whole meets the applicable standards.

|

Permission No 03/2023 Material from IHO publication S-52, Edition 6.1(.1), is reproduced with the permission of the International Hydrographic Organization (IHO) Secretariat (Permission N°03/2023) acting for the International Hydrographic Organization (IHO), which does not accept responsibility for the correctness of the material as reproduced: in case of doubt, the IHO’s authentic text or figure shall prevail. The incorporation of material sourced from IHO shall not be construed as constituting an endorsement by IHO of this product. |

Color calibration is among Hatteland Technology’s inhouse technologies. It is a staple feature of our ECDIS units, such as our 55” electronic chart table.

Related material:

This electronic chart table brings the bridge into the digital era

Let's take a closer look at optical bonding

Exploring the innovative bridge of superyacht Baglietto T52 — with Furuno Italia

Your solution partner: How Hatteland Technology can help you