What ‘type approved’ means for maritime electronics

At first glance, IT hardware on board ships looks more or less the same as conventional equipment. But it takes specialized engineering to overcome the unforgiving sea.

Professional ships operate all year round, in all kinds of waters and weather. Captains will try to avoid the worst conditions, but the harsh reality is that ships run on tight schedules and inevitably will face rough days.

As such, system integrators must prepare their systems for tough treatment, and choose components accordingly. The goal is to provide mariners with easy-to-use systems that help them operate the vessel in a safe manner.

Let’s explore what it takes for IT hardware to be labelled sea-worthy.

Power supply variations shouldn’t be an issue.

Electronics without power are no good. Which is why type approval of electronic equipment includes requirements related to the power supply.

Just like their terrestrial counterparts, onboard power networks may undergo incidents that compromise stability and cause fluctuations in voltage. Maritime electronics are therefore tested to ensure they can maintain operability even if they’ve undergone power surges or -failures.

System integrators may also seek to protect entire systems with back-up power. In that case, they will look for hardware that can run on secondary power supplies. A case in point is the Hatteland Technology X MVDs, a range of monitors that can be powered via both 115/230VAC (primary) and 24VDC (secondary).

Above: The Hatteland Technology X MVD monitors feature two power inputs: 115/230VAC and 24VDC.

Above: The Hatteland Technology X MVD monitors feature two power inputs: 115/230VAC and 24VDC.

It has to withstand strong forces and rough environments.

All onboard electronics must be able to stand up to the physical duress they will encounter at sea. And there is plenty to consider.

You have engine vibration and the ensuing resonance. Shocks from sharp waves, running aground, or even collisions. Then there are the notoriously challenging climates on board, with the full selection of temperature levels, and high relative humidity (RH) to boot. Add to that a persistent saline mist and you’ve got yourself a harsh environment for any electronic piece of equipment.

The type-approval process mirrors all of that. Manufacturers are required to perform a wide range of environmental tests because safety always comes first. You need your equipment the most precisely when the conditions are at their worst.

Above: Just an ordinary day at sea.

What is type approval?Type approval can be considered a common denominator, a qualifier, for all products intended for a certain domain or market. It is granted when a product, system, or vessel demonstrably, through testing and/or documentation, complies with a set of requirements as defined by a classification society. It is an integral part of product development for maritime applications. Different product categories are subject to different requirements. How to attain type approvalSome manufacturers do the entire type-approval process, from testing to classification, as part of the product development. Once complete, the unit is ready to be integrated in a system, with no further preparation required on part of the system integrator. The alternative is to buy non-approved gear. This may be the cheaper option upfront, but it will likely cost you lot more in the end, both in terms of time and money. That is because it requires you to run tests and certification on your own, with the added risk of delays and added costs. After all – what guarantees do you have that the product will clear all the regulatory hurdles? It's our clear recommendation you go with type-approved hardware. What certificates do I need?Project leaders will encounter numerous classification societies — DNV AS, Lloyds Register Group LTD (LR), Bureau Veritas (BV), KR (Korean Register), China Classification Society (CCS), to name a few — whose requirements differ slightly. However, they are all more or less aligned with the international standard IACS E10 Rev.8. What classification(s) to aim for depends on the type of vessel, and what territories it is intended to operate in. You can read more about classification societies here. |

Tolerance for a wide temperature/humidity range

The indoor climate of a ship varies from cold and damp to hot and dry, and everything in between.

Whether your hardware is placed in the engine room or on the bridge, you need to make sure it can handle a wide temperature range as well as high relative humidity (RH). This applies to all operational modes of the ship: In operation, in dock, and in storage.

Winter cruise: Ferries operating in the Nordics must be prepared for cold weather.

Electromagnetic compatibility (EMC) is a must.

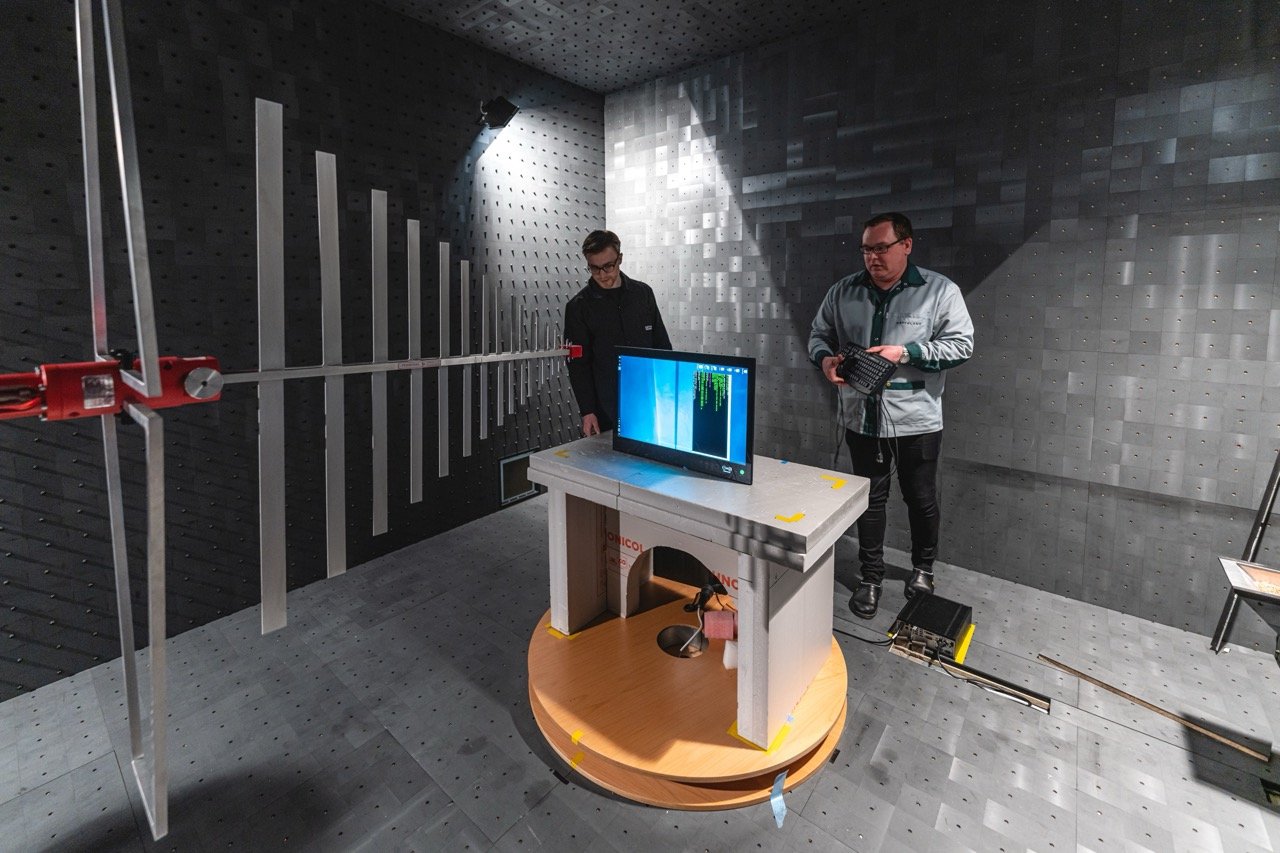

Electronic devices emit, and react to, electromagnetic radiation. Neighboring electronics can disturb each other, potentially jeopardizing safety-critical systems such as compasses and emergency radio.

Thus, in areas where proximity between hardware is unavoidable, such as on a ship’s bridge, electronics are required to be EMC shielded. The level of shielding required varies by application. Compliance is verified via standardized tests during type approval.

Above: Hatteland Technology employees prepare a maritime monitor for EMC testing.

Readability is a top priority.

Navigation is a round-the-clock activity, and mariners need pristine readability in all light conditions. True maritime monitors are bright yet glare-free during the day. At night, they dim all the way down to zero (the requirement is 1 cd/m2), preserving the user’s night vision.

For monitors and electronic chart tables used in ECDIS systems, dimming isn’t merely a nice, optional feature: It’s mandatory. Moreover, the colors must be accurate at all brightness levels, as they provide the navigation officer with important information. For instance, different shades of blue indicate different depth levels.

The importance of readability in maritime monitors cannot be overstated.

Above: Marine monitors are carefully designed to provide optimal readability in all light conditions. Here, an array of 4K monitors from Hatteland Technology as seen on the Monaco Yacht Show 2023.

Remember, cyber security is now mandatory.

Computers have already been involved in safety-critical applications on board for decades. In response to the mounting threat of cyber-attacks, and the increasing importance of onboard computer networks, classification societies have decided vessels’ cyber defences deserve the same scrutiny as the physical integrity of the ship.

As of July 1st 2024, new ships are required to implement two Unified Requirements (URs) regarding cyber resilience. According to the International Association of Classification Societies (IACS):

UR E26 covers the “secure integration of both Operational Technology (OT) and Information Technology (IT) equipment into the vessel’s network during the design, construction, commissioning, and operational life of the ship.”

UR E27 on the other hand “aims to ensure system integrity is secured and hardened by third-party equipment suppliers.” It does so by providing “requirements for cyber resilience of onboard systems and equipment and provides additional requirements relating to the interface between users and computer-based systems onboard, as well as product design and development requirements for new devices before their implementation onboard ships.”

Form-fit hardware helps futureproof the vessel.

This final consideration – form-fit hardware – isn’t actually a part of type approval. But as it affects the longevity of the ship, we include it anyway.

Ships are built to last at least 20 years. Computer equipment, which includes monitors, usually last 5–7 years. Thus, you should expect to replace the monitors at least twice over the ship’s life span.

To secure smooth replacements, opt for form-fit system hardware. It’s an approach in which the new monitor (or other equipment) inherits the form of the previous generation. Form fit ensures seamless replacements throughout the life span of a ship – whether due to component errors and repairs, or upgrades to keep pace with technological advancements – without the need for a system redesign or costly adaptations.

Learn more about marine IT hardware

The T40 line of marine monitors accommodates ECDIS, IBS, Automation, CCTV, and much more – and it does so in style.

Who needs a traditional bridge console when you’ve got three huge, state-of-the art 55-inch monitors, plus a fully integrated control system?

...........................................

To learn more about Hatteland Technology and how we can assist your project, please visit our

Marine & Offshore page. You are also welcome to browse our portfolio of marine products,

or contact us directly.

Related material:

A Quick Guide to Marine Monitors

Explore the innovative bridge of superyacht Baglietto T52 — with Furuno Italia

An introduction to computer networks on board ships

Common cyber-security vulnerabilities in ships